STAGE - 1

1. Order Approval by client.

2. Final P&I Drawing sent and approval given by client.

3. Process Design and Preparation of Specification Sheets.

4. Final GA and Foundation Drawing sent and approval

given by client.

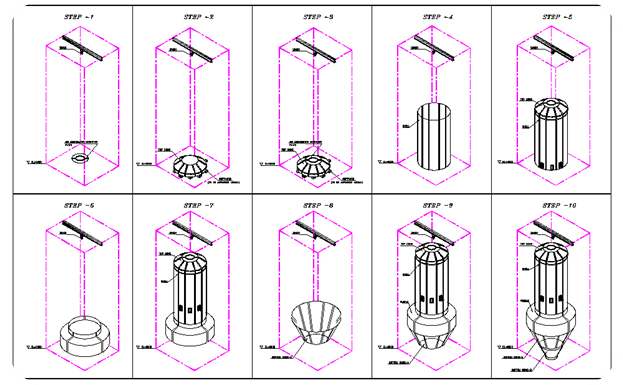

5. Mechanical Design and preparation of Detailed

Engineering Drawings.

6. Checking of Drawings and released for fabrication.

STAGE - 2

1. Estimation and Procurement of Raw Material.

2. Quality Checks on Raw Material like Material Composition Checks.

3. Fabrication along with Stage wise Inspection.

4. Final Inspection as per MOJJ QA Plan.

5. Packing.

STAGE - 3

1. Export worthy Packing followed by loading and sealing of container.

2. Transportation of container to Mumbai.

3. Custom clearance and loading on vessel.

STAGE - 4

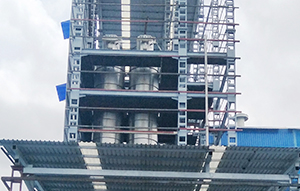

1. Unloading of container / equipment (in case of oversize cargo)at the destination port.

2. Customs clearance.

3. Internal Haulage to site.

3. Unloading material at site.

TO BE COMPLETED BY CLIENT UNTILL STAGE – 4 IS COMPLETED.

TO BE UNDERTAKEN BY CLIENT’S CONTRACTOR - STAGE 5