CAUSTIC FLAKE/ PILET/SOLID (99.9%) DISSOLVE IN WATER

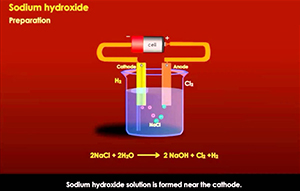

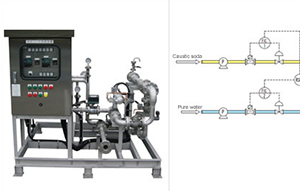

MOJJ has developed sodium hydroxide preparation system, a cost-efficient system solution specifically aimed at industries with fluctuating, but large requirements of alkaline detergents or for countries where a continuous delivery is not secured.

This solution ensures the safe and efficient preparation of soda lye on the basis of sodium hydroxide (NaOH) in solid form (pellets, flakes, beads or powder) and water.

SODIUM SILICATE STONE (99%) DISSOLVE WITH THE HELP OF STEAM TO

MAKE LIQUID FORM (50% PURIETY),

TO REDUCE COST OF TRANSPORT

The sodium silicate plays very important role in the formulation of synthetic detergent powder for its property to suspend soil in solution and to prevent subsequent depending on cloths. No other alkali is common use in detergent have as good a buffering action as sodium silicate and its effectively inhibits the corrosion of stainless steel and aluminum by synthetic detergents and complex phosphate.

For this reason sodium silicate is one of the most important components in the synthetic detergent formulation.

The sodium silicate desolation unit operates batch wise:

Sodium silicate solid vitreous form 100 % to sodium silicate solution 40-48%

The time required for complete batch including sodium silicate charging, dissolving and transferring in to separation vessel is about 4 hours

Plant capacity:

5 Metric ton to 20 metric ton

1 Batch of 100 % silicate lumps (water glass ) to obtain 40-48 % sodium silicate solution

Liquid Detergents Manufacturing Process

For manufacturing liquid detergent, both the batch as well as continuous blending processes is used.

To make liquid detergent, the dry powder is simply mixed back in with a solution consisting of chemicals and water, called as "solubilizes." These chemicals help the water and detergent to blend together more evenly. The amount of light reflected, in comparison to the amount reflected by a sample of the original fabric, is a measure of the degree of cleanliness. A reflection rate of 98 % is considered as quite good and shows that the detergent has cleaned properly.