Detergent Plant

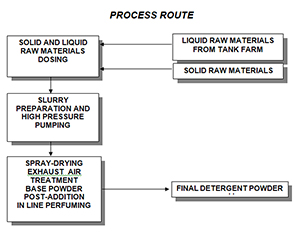

This system is designed to allow the liquid and solid raw materials automatic dosing operation and to feed the slurry preparation unit.

The dosing operation is a sequence of raw materials weighing steps and feeding into the neutralizer/slurry preparator, installed on load cells.

The raw materials weighing devices are controlled by the Computer Control System, according to pre-set formulations.

Sodium Sulphate, Sodium Tripolyphosphate and Sodium Carbonate are stored into the relevant daily silos

These silos shall be charged either manually by means of big-bags electric hoist / pneumatic system

.

All the silos are equipped with a double speed screw conveyor, automatically controlled by the load cells, to feed the solid raw materials into the slurry preparator.

Liquid components are supposed to be available at battery limits.

Liquid components dosing are automatically controlled with ON/OFF valves put on the relevant feeding lines to the slurry preparator installed on load cells.

Detergent Plant

The slurry preparation is performed to obtain a homogeneous mixture having a density of about 1.4 kg/lt and solid content up to 65% - 70%. Temperature should be such (60-70°C) as to obtain a fluid slurry.

These conditions depend on the type of raw materials used. Therefore, the checking of raw materials is important to select the operating parameters.

The solid and liquid components, are conveyed to the slurry preparator which has been designed to obtain a perfect homogenizing of the slurry components mixture and it is provided with a special high turbulence stirrer which prevents lumps formation in the mass.

The slurry preparation unit is designed also for sulphonic acid neutralization, which will operate batch-wise for quality control (constant composition and physical parameters of the slurry) and production flexibility.

The mixture is then discharged into the ageing vessel that is designed to homogenize the slurry and to ensure the required ageing time to the sodium tripolyphosphate. In this vessel it is possible to charge the recovered water/slurry coming from the collecting vessel pit.

The ageing time can be controlled by varying the liquid level in the ageing vessel.

The main advantages for the slurry preparation system are:

After ageing, the slurry passes through which retains any eventual ferrous component and then through a self-cleaning filter called vibosifter which retain all impurities eventually present in the slurry.

By means of a booster pump the slurry is fed to the high pressure pump

The high pressure pump has been specifically designed to handle viscous and abrasive slurries at a pressure up to 60 barg and to keep the pre-set pressure value constant in order to feed the spray nozzles in a uniform manner.

Detergent Plant

Spray drying tower

The slurry is sprayed at high pressure by a nozzles system from the upper part of the spray drying tower

The slurry meets the hot air counter-currently and the dry powder is discharged from the bottom of the tower, in form of beads.

The special design of the hot air distribution chamber allows operation with high differential temperatures i.e.: air inlet temperature up to 325-400°C, exhaust air outlet temperature down to 100 TO 110°C with consequent optimum drying efficiency.

The tower is fitted with inspection doors, explosion proof doors, inspection holes for lighting, etc.

The high efficiency bag filter, installed downstream the spray drying tower, recovers the fines entrained by the exhaust air; fine particles are continuously collected and recycled in the spray tower by means of fines recovery injector and fines recovery fan / by gravity divert in to product

The exhaust air is then sent to the atmosphere by means of extraction fan

Typical spray-drying tower operation conditions are listed here below:

All the operating conditions are adjusted by setting the operation parameters as: fuel consumption, air flow, slurry concentration and all pressures/temperatures.

Nozzles circuit

After the right pressure has been set, the slurry is sent to a spray nozzles installed in the upper part of the spray tower on which are connected the spray nozzles and the relevant shut-off and service valves, designed for control operation/ manual

The number of nozzles installed is higher than the number of nozzles used; therefore it will be possible to replace and clean the clogged ones without reducing the capacity of the tower.

The nozzles are constructed with high hardness material, as they must stand a long time operation with abrasive slurries.

The special nozzle design allows optimum spray distribution of the sprayed slurry in the drying chamber of the tower, where it is dried with hot air. A homogeneous powder is collected at the bottom of the spray tower having the required residual moisture, bulk density and particle size.

Cleaning ring

The spray-drying tower is equipped with a special cleaning system that can be operated also during plant running, ensuring a constant and perfect cleaning inside the tower.

This system consists of a steel ring fitted on the external perimeter with a double layer of flexible scraping blades made of heat resisting spring-type steel.

The ring is driven by means of an electric winch system with pulleys and ropes

Hot air generation

The characteristics of the powder beads are largely determined by speed and temperature of the hot air stream.

The hot air is generated in a horizontal type furnace purposely designed to obtain a smokeless combustion. The proposed unit is based on the combustion of heavy oil, as per client material safety data sheet, stored into the heavy oil tank. Alternatively, the burner can be designed to process the most commonly available fuels (ranging from natural fuel gas to heavy fuel oils), without causing inconveniences or affecting the whiteness of the final powder.

The hot air generation group is provided with a liquid fuel burner a combustion fan and dilution air fan and the fuel feeding unit; a local control panel includes the start-up control instruments and safety equipment.

The hot air is conveyed to the lower part of the spray-drying tower and meets the product counter-currently.

The exhaust air fan and the dilution air fan control the air-flow passing through the tower and determine the pressure conditions of air circuit.

Detergent Plant

Base post-addition

The detergent powder coming from the spray drying tower can be used as such or can be mixed, in preset quantities and proportions, with enzymes and speckles according to the client final formulation for product dedicated to washing machines (BOOM powder recipe).

These components are usually added to the base spray dried powder since, due to their physical properties, they cannot be added into the slurry or heated in the spray drying tower.

The base powder, collected in the hopper installed on load cells, is dosed by means of proportioning belt while enzymes and speckles are dosed by means of loss in weight systems, respectively

Final perfuming

The stream of powder coming from the conveyor belt is sent to final perfuming where the perfume, coming from the perfume vessel is dosed by pump according to the flow rate of base powder.

The perfume is put in contact with the powder in a perfuming vessel where the perfume is fed in spray form.

The perfumed powder is sent to feed the client packaging lines

1. LABS storage tank : ( LABS purity 90 /96 %)

2. Caustic lye storage tank: ( 45 % purity )

3. Sodium silicate solution storage tank : ( 48 to 50 % solution)

4. Process water tank

Detergent Plant

The synthetic detergent powder production plant is designed for a nominal capacity of 500 kg per hour to 10000 kg/h of base detergent powder coming from the bottom of the spray drying tower.

The synthetic detergent powder production plant is composed of the following units:

A detailed process description of the units of base plant configuration is given here-below.

FORMULATION

> Active Matter Range 1 to 29 %

> Phosphate free product

> High foam, low foam, hand wash powder, washing machine powder

> Up to100 different preset formulation can be store in computer memory

> Moisture of product range 1 to 10 %

It is an alternating pump with single-acting plungers. Pump delivery flow can be continuously adjusted according to the plant capacity, by regulating the rotation speed, through a frequency variator on pump motor.

The constant high pressure and the regular pumping, achieved also with highly concentrated slurry, allow obtaining a final product of strictly constant characteristics.

A safety valve installed on the high pressure delivery pipe, prevents the build-up of harmful overpressure.

From the high pressure pump, the slurry is fed to the spray tower through a special pipe, equipped with a high pressure surge vessel smoothing out flow pulsations due to the pump alternating strokes, before reaching the nozzles circuit

The plant is operated by computer control system, specially design for reliable and performing operation with an easy to use and friendly operator interface. The computer control system ensure a trouble free plant operation with the automatic control of all the critical process parameters. It also guaranty a high dosing accuracy and therefore the accuracy and consistency of the product formulations. More-over the computer control system reduces to minimum labor requirement for plant operation. Up to 100 different presets formulations can be stored in the computer memory and the system automatically adjust all process parameters and dosing devise achieve the final formulation selected by operators The computer control system is built using the most advanced architecture that included a PLC for process and production data control. The PLC foreseen for digital and analog signals handling and it is provided with one or two CPU designed to make all controls ( PID loop, data acquisition, alarm, interlock, sequence etc. ) by programmable logic.

Sections